Boeing Factory Tour, and Future of Flight Museum, Everett, Washington, June 2014

Edited by David Barth, December 2014. Photos are by David Barth.

Statements herein are personal observations and opinions gathered from reading newspaper articles and periodicals, especially Aviation Week & Space Technology, and are not attributed to Boeing tour guides who have a strict format to cover during a tour.

The Boeing factory in Everett, Washington, north of Seattle, is next to Paine field, a public-use airport. Boeing has had the field extended long enough to handle its largest aircraft, the 747 series of Jumbo Jets. It is not known if an Airbus A380 could land and takeoff at Paine field. In any event, it is unlikely that would ever happen except in a dire emergency.

|

| Boeing's Everett, Washington manufacturing facility. |

This building, at Boeing's Everett, Washington manufacturing facility, is one of the largest in the world. It is so expansive that it has its own weather system inside. The photo was taken on the way to the Boeing Future of Flight Museum. From the nearby Boeing Future of Flight Museum, visitors can take a Boeing tour bus that takes them to see the inside of this building.

However, no cameras, cell phones, or any sort of recording equipment is allowed in the manufacturing facility. This is, of course, to reduce image collection by competitors, of which there are many around the world including Europe, China, Brazil, Russia, and India. Boeing still reigns as the leader in aircraft.

For this reason, the first batch of photos in this collection were taken from the upper viewing deck of the Future of Flight Museum which stands apart from the manufacturing facility, and the last group of photos was taken inside the Future of Flight Museum, itself. This museum is much smaller than the "king of aviation museums" at Boeing Field, the Boeing Museum of Flight, at Boeing Field, south of Seattle.

Perhaps surprisingly, Boeing displays equipment from other aircraft manufacturers as well as its own, a refreshing attitude in such a competitive field of endeavor.

The manufacturing process is huge, complicated, and fascinating, with moving production lines for several Boeing aircraft models. Boeing continually tries to make the build process more efficient to keep costs as low as possible in the very competitive aviation market.

|

This is an old railroad crane at the Whitney railroad

location, which is now a little-used siding. |

|

This is an old railroad crane at the Whitney railroad

location, which is now a little-used siding. |

|

This is the entry hall at the Boeing Everett Future

of Flight Museum. |

|

| This appears to be a new Boeing 747-8, cargo version. |

This plane has either had its fuselage wrapped for weather protection until delivery or has been freshly painted in white prior to adding specific airline logos. The 747-8 passenger and cargo planes were introduced around 2012.

When the Airbus A380 was planned, Boeing decided not to try to copy it with a full, double-deck 747. Instead, the company somewhat expanded the upper deck. Boeing had long ago perfected the wiring design necessary to service two decks during the early 1960s. Airbus engineers took a long time to accomplish this feat, although they had two full-length decks to accommodate.

Boeing is said to be one of the best employers in the world, and that is evident in its relationship with employees and the unions. There is very low personnel turnover, and most employees make Boeing a career. That said, if this writer were starting out again, I would head for Seattle to seek employment with Boeing, although jobs are usually scarce except when an expansion is planned. Most employees start at a low level and work their way up the ladder as they prove themselves and learn the lessons because advancement is usually from within the existing work force.

|

| This is a telephoto view of Mt. Rainer. |

It is the tallest mountain in the lower forty-eight, rising over 14,000 feet. It is volcanic, and if it ever blows, it will raise havoc with the surrounding area. As of 2014, there were no known reports of impending activity.

|

This appears to be an old biplane of the Moth series,

perhaps a Gypsy Moth, in the traffic pattern at Paine Field. |

|

This and some following photos are of newly

manufactured Boeing planes that have come out of the paint

shop or are awaiting paint at Boeing's paint

facility at Paine Field. |

The four planes on the right are Boeing 787s. In fact, the plane on the far right has "787" painted on its tail. Distinctive features of the 787 include a bullet-shaped nose and shark-fin-like wing tips, as seen from above. The plane at the left appears to be a "Silkway" 747-8 cargo version.

|

| This is the control tower at Paine Field. |

The 747-8 cargo versions covered in green plastic wrap are awaiting paint. The protective covering reduces the chances of scratches and pitting from wind-blown sand and pebbles and the hands of man. The 747-8 cargo planes can be identified by the short upper deck that has only three windows on the side.

|

| Lufthansa 747-8 passenger version. |

The 747-8 passenger version is identifiable by the windows along the upper deck. There are, perhaps, a dozen more windows than on the upper deck of an older 747-400.

|

This is probably a 787 having its interior completed

for delivery to Qatar Air. |

Note the front and rear doors have rain hoods (it rains along the coast of Washington), and it is assumed that seats and interior accoutrements are moved into the plane via the stairways. Interiors generally are not installed during manufacture until it is assured that a plane is to be delivered to a specific airline, at which time it is painted with the airline's desired design and the selected interior is installed. Airlines specify the interior option they want, and the airplane manufacturer installs it. When you sit in the seat of an airplane, remember that the interior is what the airline ordered, not what the manufacturer mandated.

|

| A United 787. |

Parked in the same orientation as the Qatar 787, above, this United is getting finishing touches prior to delivery. United is one of the larger 787 customers. The 787s will replace aging 767s and provide a much lower fuel usage.

|

Thai Airways 787 appears to be set up for installation

of the interior. |

|

| Thomson Airways 787 at some phase in pre-delivery. |

The stairways, like the one in the left foreground, have either been moved away from the aircraft after the interior has been installed, or they are about to be put up to the plane for the installation process.

|

| Boeing Manufacturing Tour, 2014. |

|

| Boeing Manufacturing Tour, 2014. |

|

This is an Angola 777. The Triple Seven is an

efficient workhorse in many fleets. |

|

The 747-8 in the background appears to be polished aluminum,

but it is just the protective coating reflecting light. |

After the coating has been removed, the plane will go into the paint hangar. The 787 in the foreground has had its white base coat applied and is awaiting an airline's logo to be applied.

|

This appears to be a 777 with its protective coating

on the fuselage, prior to being painted. |

A few items are being worked including the installation of a right slat near the right wing tip and leading edge deicing surfaces on the vertical stabilizer. Generally speaking, instead of inflatable deicing boots, jets use hot surfaces to prevent ice from forming on leading edges.

|

| Boeing 787s. |

The bullet-nose profile of the 787 is particularly appealing and perhaps, more aerodynamically efficient than conventional noses where the windscreen angles sharply upward from the nose. These two planes have had their white base coat applied and are awaiting airline logos to be applied.

|

| Boeing Manufacturing Tour, 2014. |

|

| A biplane in the pattern at Paine Field. |

|

| Two Boeing 787s. |

This picture shows two Boeing 787s that have come out of the paint shop with the basic white coat and standing in front of one of the world's largest buildings, Boeing's Everett manufacturing facility where 787s ad 747-8s are built.

|

Boeing paint buildings at Paine Field across the

road from the huge manufacturing building. |

|

| This is a display of a Boeing 747-8 tail. |

|

This is the Boeing Future of Flight Museum in

Everett, Washington. The bigger Boeing museum is at Boeing

Field, south of Seattle. |

|

| Everett's Boeing Future of Flight Museum. |

|

| Everett's Boeing Future of Flight Museum. |

|

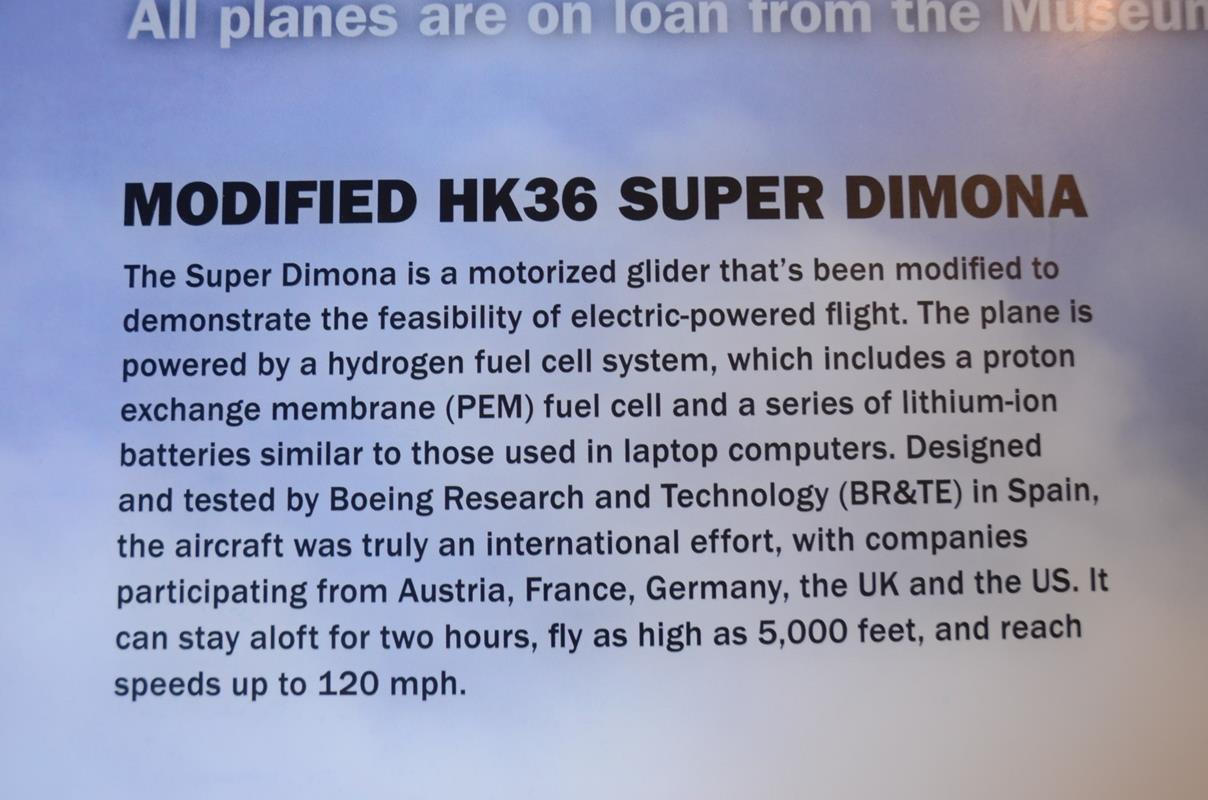

| An electric airplane at Everett's Boeing Future of Flight Museum. |

|

| An electric airplane at Everett's Boeing Future of Flight Museum. |

|

| Everett's Boeing Future of Flight Museum. |

|

| Everett's Boeing Future of Flight Museum. |

|

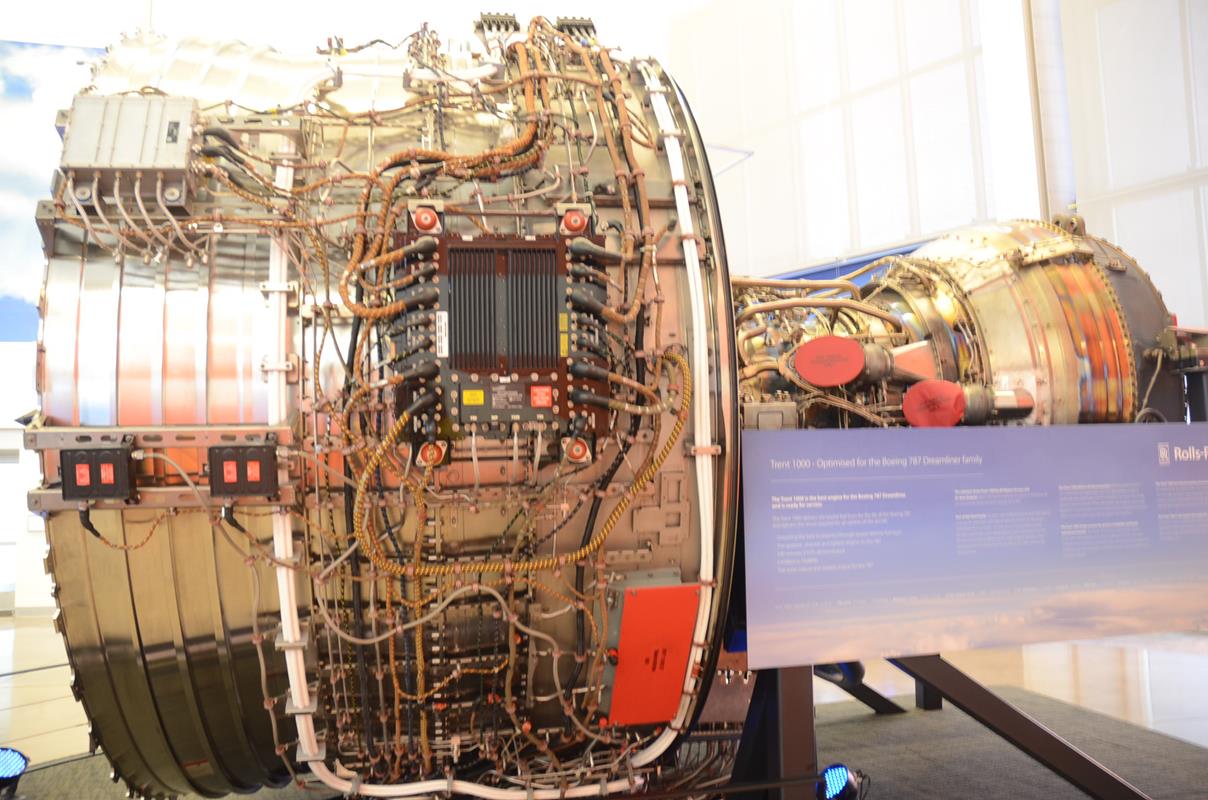

| Mockup of an engine used in the Boeing 787. |

|

| This picture illustrates why jet engines are so complicated. |

|

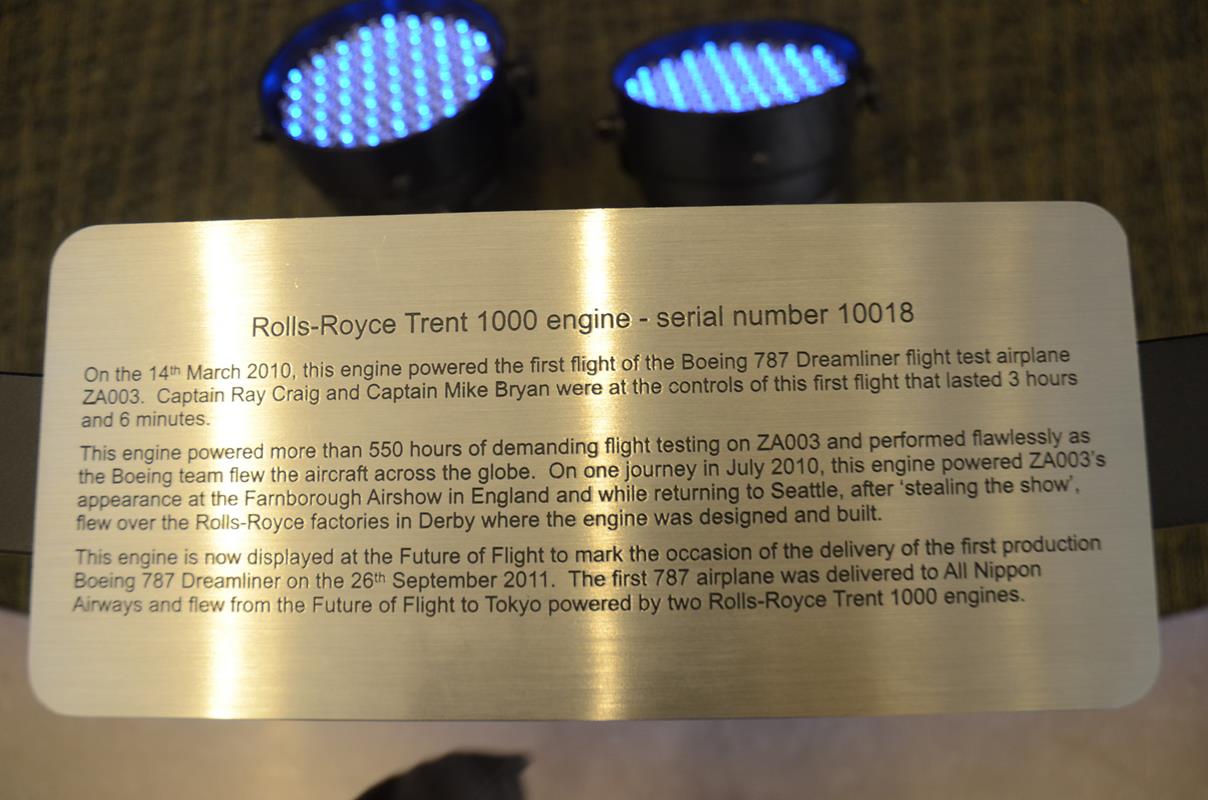

Trent 1000 jet engine, one of the engine options

for the 787. |

|

| Boeing Manufacturing Tour, 2014. |

|

Windows on airliners are small and too low for most

modern passengers. |

More than fifty years ago, when jet airline windows were designed and placement was selected, passengers were, generally, shorter than they are today. For example, the top of a traditional airline window is at my chin. To see out the window, I must crouch in my seat to look out. The only way to really see out is to hold my point-and-shoot camera to the window and look down at its display panel.

Boeing recognized this problem and has supposedly corrected it by putting larger windows in the 787. At the time of this writing in 2014, I have not flown a 787, but I look forward to a flight in one, soon.

|

| Everett's Boeing Future of Flight Museum. |

Boeing reaches out to recognize technology anywhere in the world, even from competitors. The display with the blue seats at the right of the plane's nose wheel were provided by EADS, a European aviation manufacturer.

|

| A mockup of a possible business jet seating arrangement. |

|

| The relative size of a nose wheel. |

|

This is a picture of me taken at the Boeing Future of

Flight Museum. |

I stood in front of a green screen so that the background of a Boeing 787 could be placed behind me. I have no idea why the "Boeing" logo has been partially painted out on the aircraft. This photo of the 787 was probably taken at Paine Field.